As I was getting more and more confident with printing and using different materials I finally got to the point that I wanted to make some motorcycle parts that require strength.

In this particular case some sprocket used in specific bikes to show speed and keep milage. The original parts costs around € 30,= and tends to fail on a regular basis. So printing it for a few EUROs could be a win.

But, printing with Nylon turned out to be not as straight forward as the other filemants I used so far.

First I started off with drying the filament, as nylon is really attrachting moisture rapidly.

My printer software did not have a default setting for the nylon filament, so started with ABS settings. The first 2 layers seemed to be doing fine, but soon the whole project loossend from the bed and I stopped it.

Then I actually found the temperature setting from the specific filament. Created my own Nylon settings with those temperatures set and went for a second try.

First (approximately) 10 layers looked great, and I thought I was going for succes, but again the project didn't stick to the plate.

Increased bed temperature, but again failure.

Used glue to the plate, and now it seems to keep sticking to the plate, but halfway through the print started failing again.

Some more research showed that I might have to tweak the retraction length. Default was 1 mm, and raised it to 1,5 mm.

Finally the print came out complete !!!!!

For repetition sake I printed a second one straight after the first, and also success. And later on, I printed another nylon project with same settings, and that also worked great.

So, if you're new to 3d printing, don't give up when things fail. Just keep on researching and tweaking your settings. In the end you will end up with a working setup.

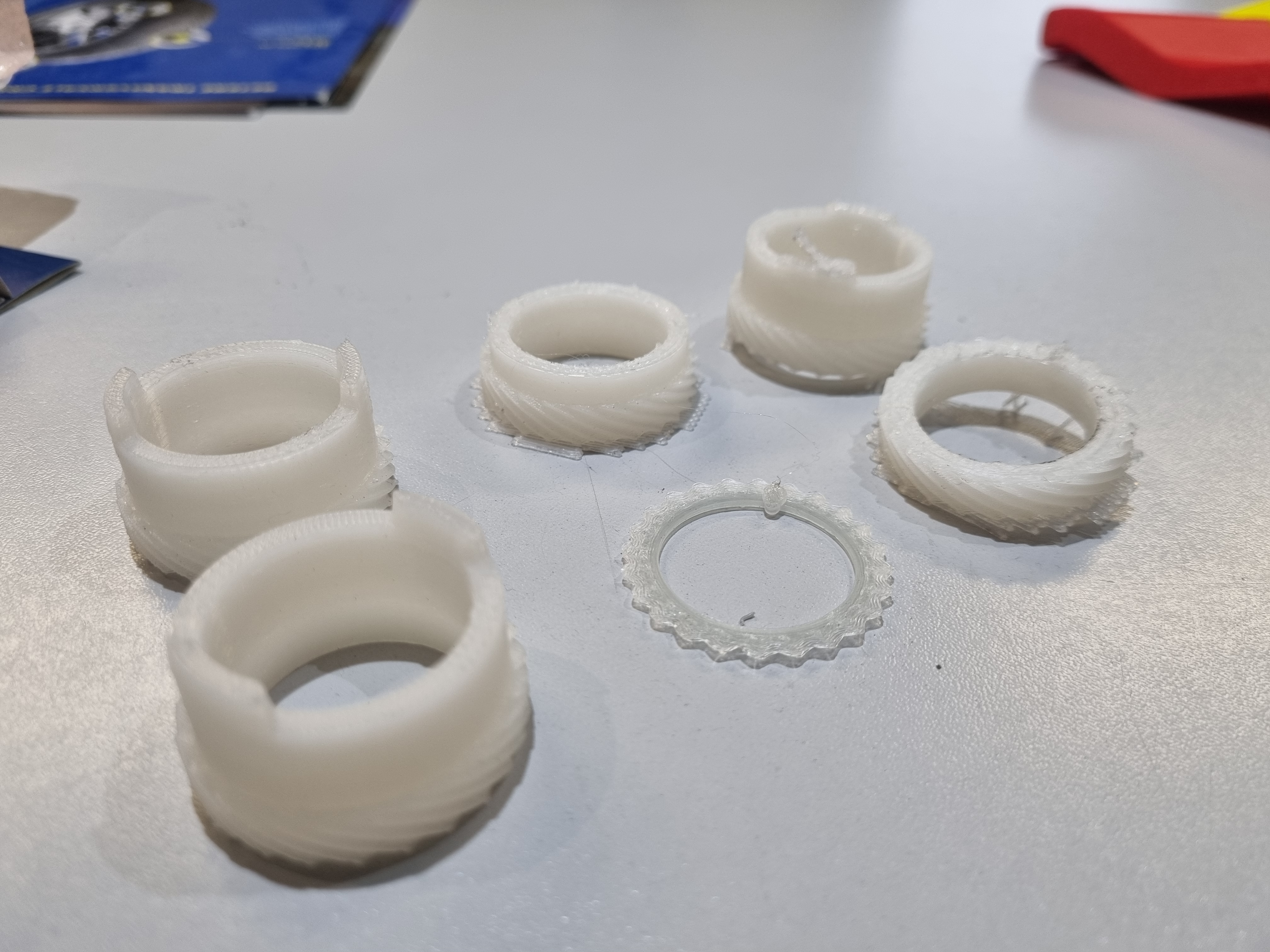

The picture shows some failures (the 4 parts on the right) and the 2 first succesfull prints.